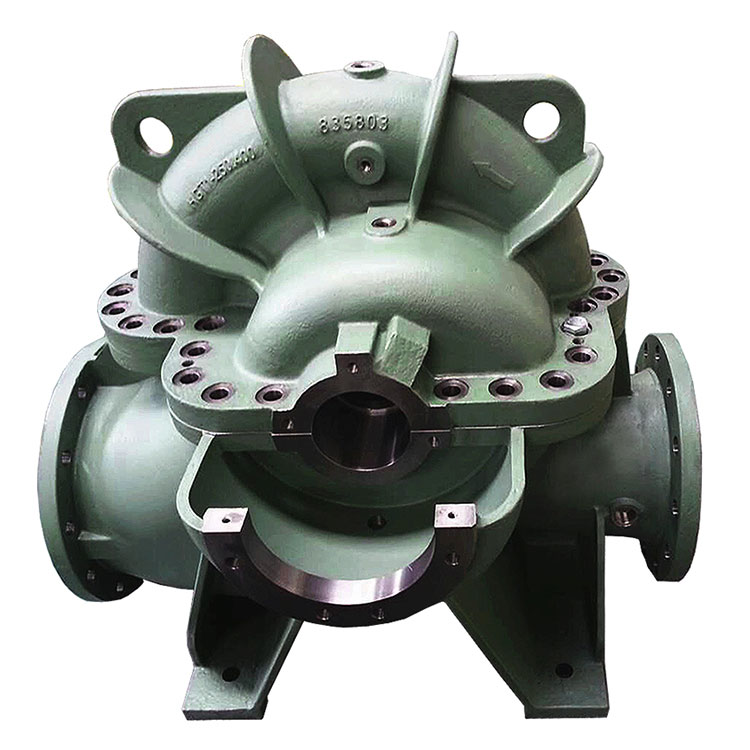

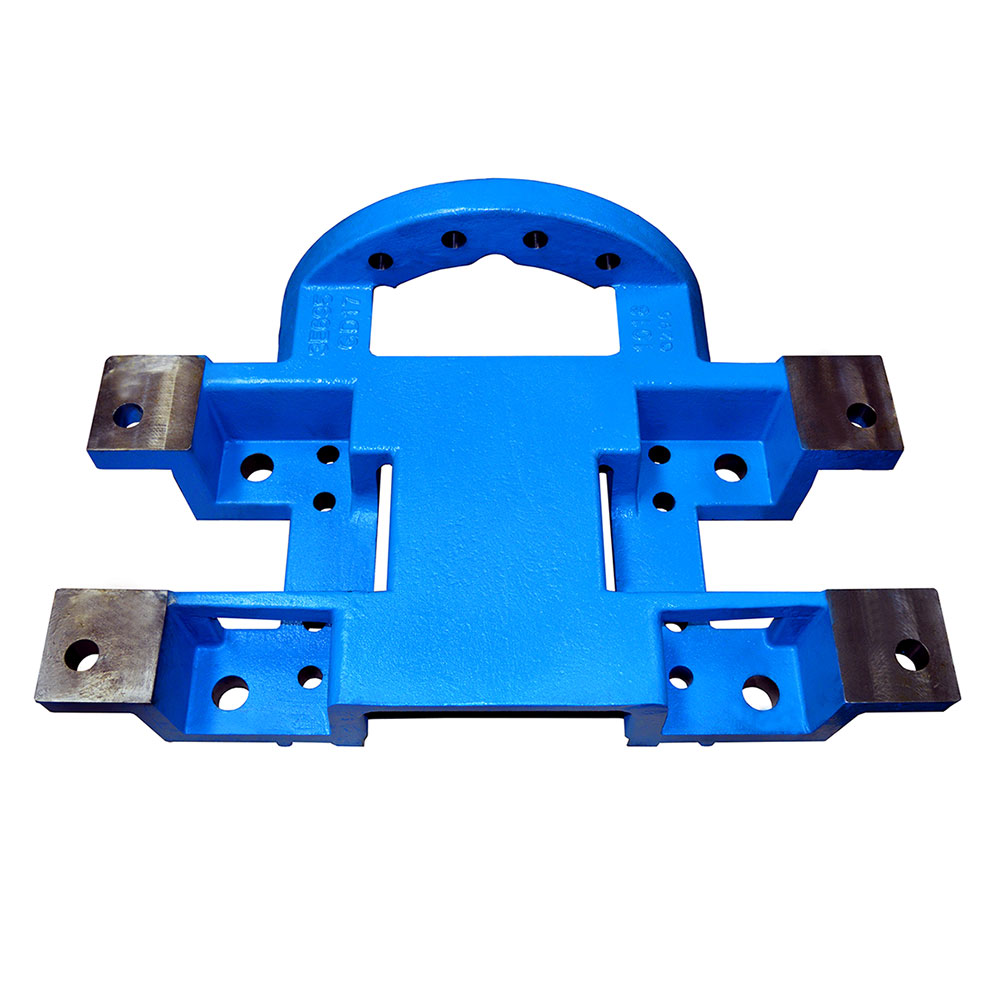

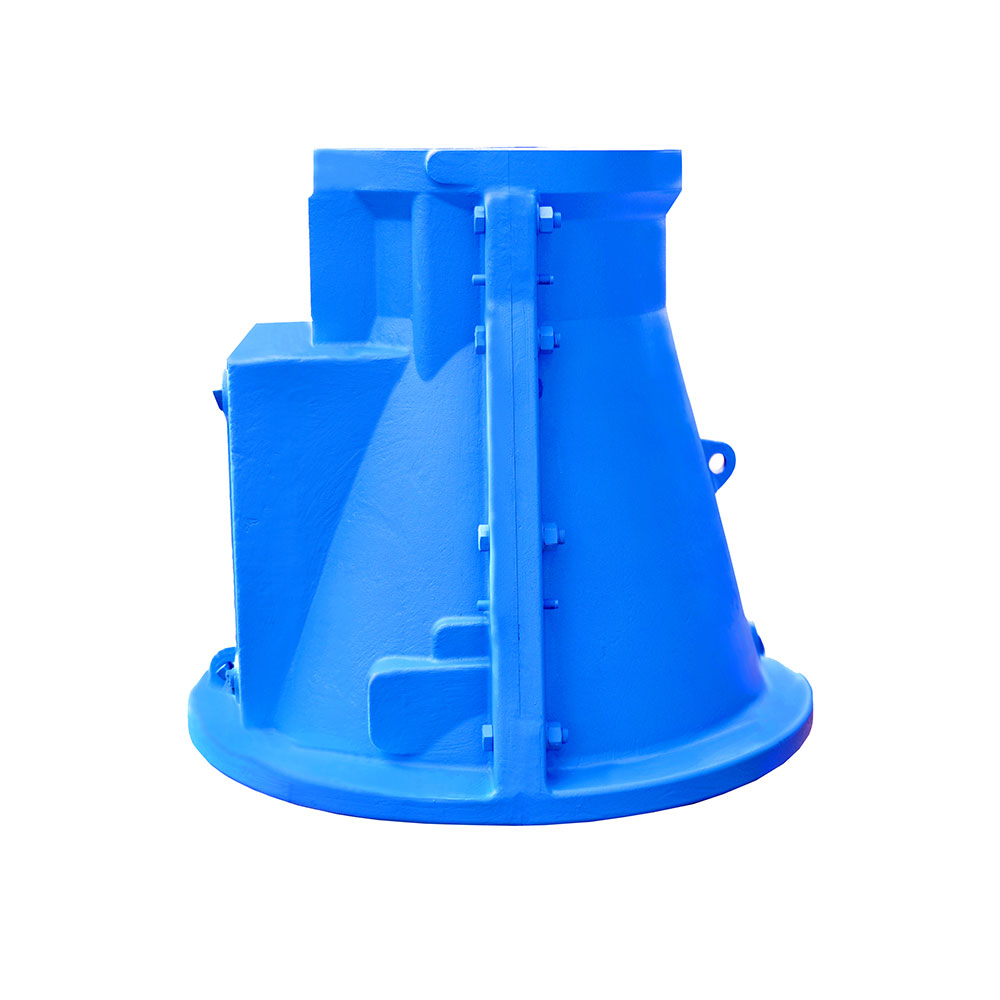

Our foundry expertise rivals the top foundries in the globe so we are able to pour more than 35,000 tons of cast and ductile iron parts annually. From the in-house design and manufacture of the patterns to the final shake-out, shot-blasting, and deburring, we employ state-of-the-art equipment and controls to ensure defect-free, aesthetically pleasing cast and ductile iron castings.

What We Do

FOUNDRY

MACHINE SHOP

We utilize over 160 CNC machines to machine the 750,000+ parts that we cast every year. Agile machining cells, in-house designed/built fixtures, and a sea of pre-set cutting tools enable us to be responsive, drastically reduce set-up times and cost to our customers.

QUALITY

The GBS Casting team takes extreme care in our dedication to Quality. We believe quality begins and ends with our entire team, not just the Quality Assurance Department. All of our 750 employees are meticulously trained at the outset of their career at GBS casting and are provided ongoing training to ensure consistent results.

ENGINEERING

Our team of 60 engineers will work with your design team to ensure that we design processes that completely satisfy the intended design of your products. We use your 2D and 3D files to generate our internal process documentation. If you desire, we can recommend slight changes to the design of your parts to make them more manufacturing-friendly which will result in highly cost-effective parts.